Category

OEM Stainless Steel Precision Casting Pumps Lost Wax Investment Casting Pump Body

OEM Manufacturer Stainless Steel Precision Casting Pumps Lost Wax Investment Casting Pump Body Our Advantage: All of our

Basic Info.

| Model NO. | PM01 |

| Surface Roughness | Ra3.2 |

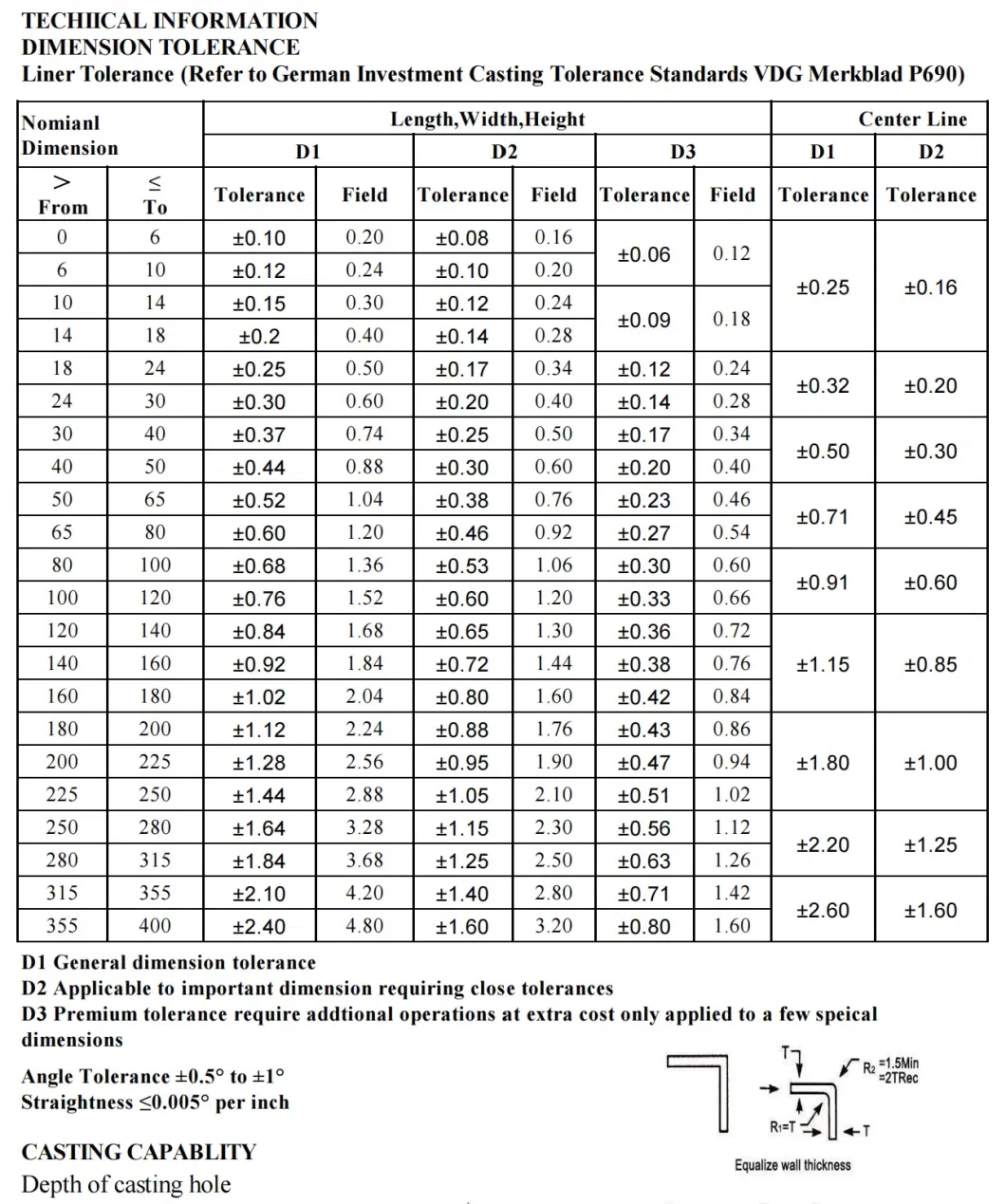

| Machining Tolerance | Refer to German Investment Casting Tolerance Stand |

| Standard | AISI |

| Certification | ISO 9001:2008 |

| Customized Support | OEM |

| Type | Machinery Equipment |

| Service | One Stop Service. Machining-Assembly |

| Transport Package | Bubble/Poly Bag+Carton Box |

| Origin | Guangdong |

| Production Capacity | 60 Tons/Month |

Product Description

OEM Manufacturer Stainless Steel Precision Casting Pumps Lost Wax Investment Casting Pump Body| Product Name | Pump Body |

| Brand name | Zeren |

| Material | Stainless steel |

| Feature | Pump Valve Casting Part |

| Process | Investment Casting |

| Certification | ISO9001:2015 |

| Customized support | OEM |

| Product General Specs: | |

| Material | Austenitic stainless steel: 201, 303, 304, 316, 316L, 1.4581, scs14, scs16 |

| Hardened stainless steel:17-4PH, 410, 420, 440C | |

| Alloy cast steel: 4140, 4150, 4340, 8620, GS-25CrMo4 | |

| Casting alloy tool steel: CS-2, CS-7, CrWMn | |

| Carbon steel: 1020, 1025(WCB), 1030, 1040, 1045, 1050 | |

| Weight | 1g-30kg |

| Casting tolerance | CT4-CT7/GBT6414-1999; VDG Merkblad P690 |

| Surface Roughness | Ra1.6-Ra6.3 |

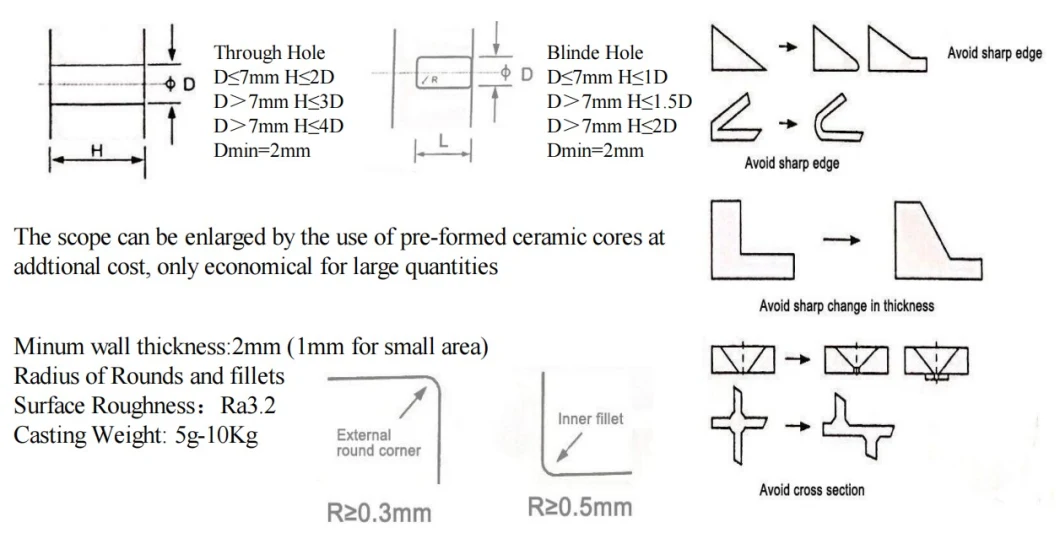

| Thickness | Min 2mm (1mm in Micro-region) |

| Casting Radius | Round radius ≥0.3mm, Internal fillet radius≥0.5mm |

| Blind Hole Depth | Max 30mm (Diamter 10mm) |

| Machining | Turning,Milling,Drilling,Boring,Threading, Grinding,CNC Machining & test equipment |

| Heat Treatment | Annealing,Hardening, Normalizing,Carburizing, Aging |

| Surface Finishing | Black Oxide,Black Coating,Anti-Pollution Flashover Coating,Mirror Polish |

| Industry Standards | ASTM, ICI, BS, DIN, JIS, ISO |

| Design Software | Pro-E, UG,Solidworks, AutoCAD |

| File Format | IGS, STP, XT, PDF, JPEG, JPG |

Our Advantage:

All of our items is silica sol investment casting instead of water glass investment casting.Water glass method dewaxes into the high-temperature water, and the ceramic mold is made of water glass quartz sand. Silica sol method dewaxes into the flash fire, and silica sol zircon sand makes the ceramic mold.

The silica sol investment casting can get a better surface roughness Ra3.2.

Product Example

Company Introduction

Foshan Zeren Precision Casting Co.,Ltd. is founded in 2009, with a precision casting plant and a mechanical processing plant, located in Zhaodaxinzhao Industry Park in Shishan Town of Nanhai District of Foshan City, Guangdong province. We use advanced investment casting(lost wax casting) process for precision castings production, which are made of Stainless steel, carbon steel and alloy steel. We can also provide subsequent machining of casting, and have passed and implemented the ISO9001:2015 quality management system.

Why Choose Us

Tolerances For Investment Casting

FAQ

Q1: What sizes of parts can Zeren produce? A:Zeren pours a wide variety of parts, weighing anywhere from a few ounces to as much as 250 pounds. Q2: What alloys does Zeren pour? Can I get my logo on my part? A: Zeren pours a wide variety of alloys, pretty much anything, except iron, lead, vacuum grade materials or exotics. Of course, be as creative as you want. Q3: What kind of surface finishes can be produced? A: Zeren offers an assortment of surface finishes. From polished zinc plating to chrome, you can view all of our surface finishes, here.

Q4: How long will it take to receive a quote?

A: Tell us when you need it and we'll tell you what we need to accomplish it. The more information you can provide our engineers, the faster we can return your completed quote.

Q5: What kind of CAD files can I send? How do I upload a CAD/large file to you? A: You can send anything you run but the most beneficial are UG, STP, or Parasolid. Q6: Can I create prototypes with investment casting? A: Yes, Zeren plays a major role in expediting time-to-market for new products, being well versed in utilizing prototyping to simulate a production part in a minimal time frame.

Certificate