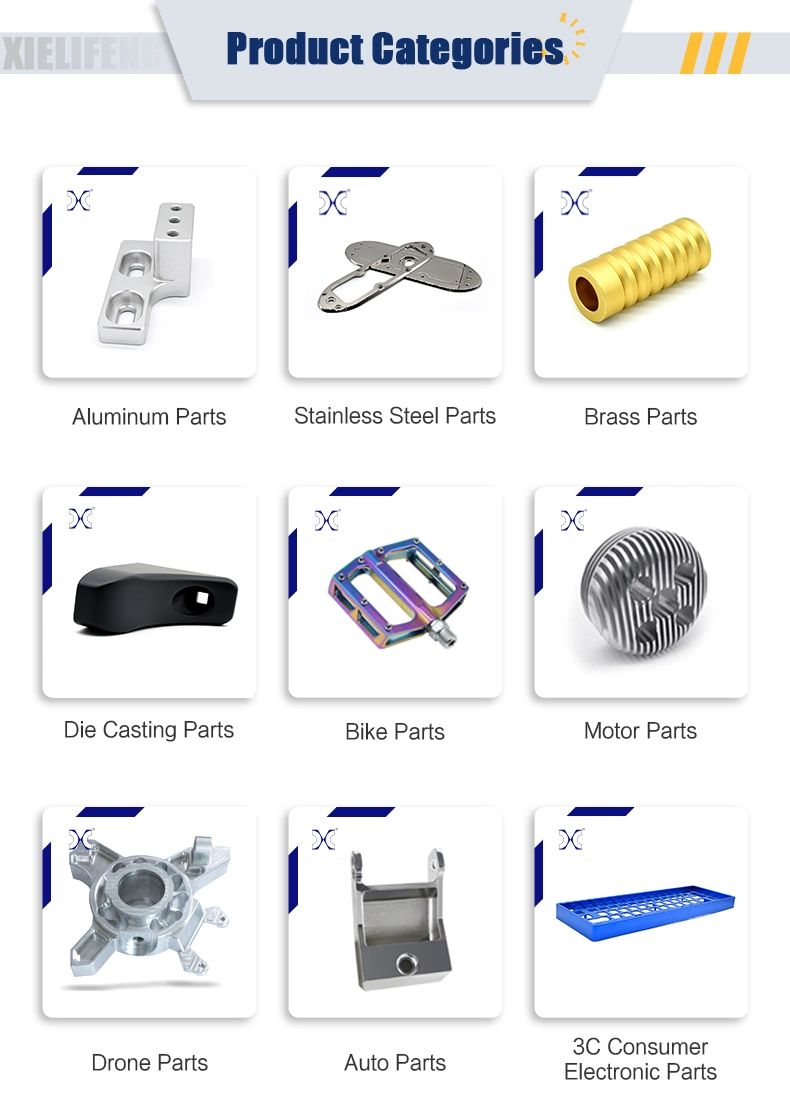

Category

Motor/Motorcycle/Auto Spare Spare Part ADC12/A356/A380/A319/A380 Precision Aluminum

Package Size 10.00cm * 5.00cm * 5.00cm Package Gross Weight 0.100kg Factory Motor/Motorcycle/Auto Spare Spare Part ADC12

Basic Info.

| Model NO. | OEM-3 |

| Machining | CNC Machining |

| Material | Aluminum |

| Surface Preparation | Spray Coating |

| Pressure Chamber Structure | Vertical |

| Tolerance Grade | 4 |

| Casting Surface Quality Level | 1 |

| Certification | ISO 9001:2000 |

| Service | One Stop Service |

| Machines | Casting |

| Popular Color | Black/Blue/Dark Grey/Orange/Red |

| Main Prosess | Die Casting |

| Other Service | Assembly, Die Casting Service |

| MOQ | 200PCS |

| Logo Service | Support |

| Sample Service | Avaiable |

| Style | Custom Metal Parts |

| Part Name | Die Casting Aluminum Parts |

| Surface,Treatment | Anodizing/Polishing/Plating/Painting, etc |

| Size | Custom Avaiable |

| Roughness | Ra0.2-Ra3.2 (Customized Avaiable) |

| Drawing File | Step, STP, Pdf, Dwg, Dxf, etc |

| Tolerance | +-0.02mm(Customized Avaiable) |

| Transport Package | EPE + Paper Box |

| Specification | Custom |

| Trademark | Custom |

| Origin | China |

| HS Code | 7615200000 |

| Production Capacity | 50, 000, 000 |

Packaging & Delivery

Package Size 10.00cm * 5.00cm * 5.00cm Package Gross Weight 0.100kgProduct Description

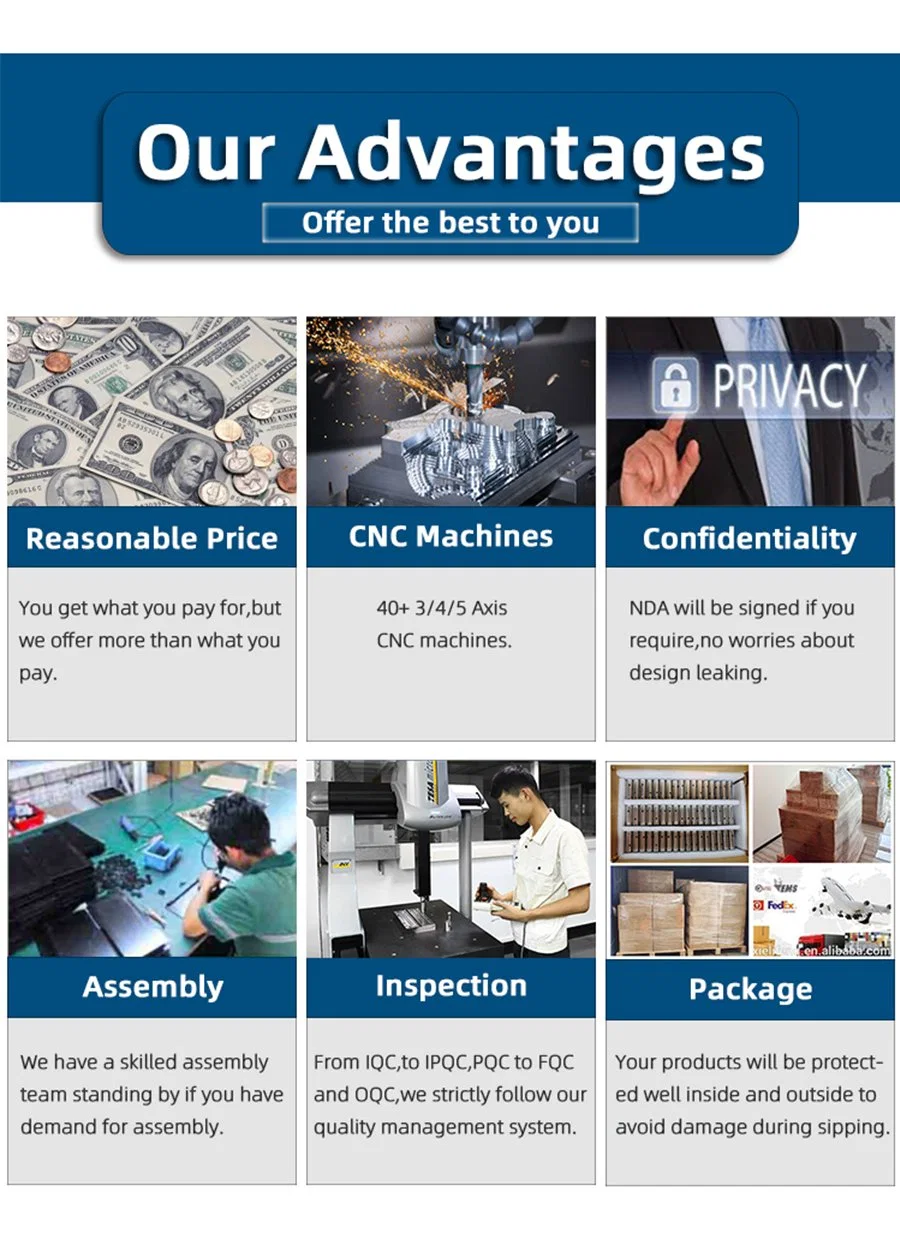

Factory Motor/Motorcycle/Auto Spare Spare Part ADC12/A356/A380/A319/A380 Precision Aluminum-Zinc Alloy High Pressure Die Cast Gravity Casting PartXielifeng Tech is located in Shenzhen, China, which focuses on CNC machining, including milling, turning, auto-lathe, die casting. Both metal and plastic material are within our capability. We provide a one-stop service, from professional design analysis, to free quote, fast prototype, ISO standard manufacturing, to safe shipping and great after-sales services. During these years, we have win lots of trust in the global market, most of them come from North America and Europe. Now you may have steady suppliers, but still hope you can keep us in the archives to get more market news.

About Die Casting Production

- Automatic production, die casting machine with ABB robot.

- Our engineers have rich mold design and manufacturing experience in diecasting industry.

- Process: high presure/low presure/gravity die casting

- Surface treatment: anodizing, oxidizing, sandblasting,brushing,polishing,plating, powerder coating,PVD/DLC coating, heat-treatment, passivation, QPQ, and so on.

- Tolerance: +/- 0.03-0.05mm avaialble

- Salt spray test :48-720 hours, according to different surface treatment

- Molds belong to customers who pay for it.

About Drawings and Delievery

- 2D and 3D drawings types: JPG,PDF,STP,IGS,DWG,X-T, etc.

- Certificate:SGS,ROHS,IATF16949,etc

- Delivery time:25-45 days for mould , 20-30 for mass production

- 100% inspection before delivery.

| Service | Custom Die Casting Parts of Most Materials |

| Quotation | According to your drawing(size, material, thickness, processing content, and required technology, etc) |

| Tolerance & Surface Roughness | +/-0.005 - 0.01mm & Ra0.2 - Ra3.2 (Customize available) |

| Materials Available | Aluminum, Zinc, Stainless steel, Iron, etc. |

| Surface Treatment | Polishing, general/hard/color oxidation, surface chamfering, tempering, etc. |

| Processing | Die casting |

| Payment method | Our business face global. and support credit cards, T/T, L/C, Paypal, etc. |

| Drawing Formats | PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF |

FAQ: Q1: Where can I get product&price information? A1: Send us an inquiry on the page or e-mail, we will contact you after upon receipt of your mail.Q2: How soon can I get samples and how much the fee?A2: Depending on your specific project, it usually takes 10 to 20 days. the fee depends on your parts drawing, and the fee will be returned to your bulk order.Q3: How to enjoy the OEM services? A3: Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you.Q4: Can you make machining parts based on our samples? A4: Yes, we can make measurements based on your samples to make drawings for machining parts making.Q5: Is it possible to know how are my products going on without visiting your company? A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.Q6: Will my drawing safe after you get it? A6: Yes, we can sign the NDA before got your drawing.