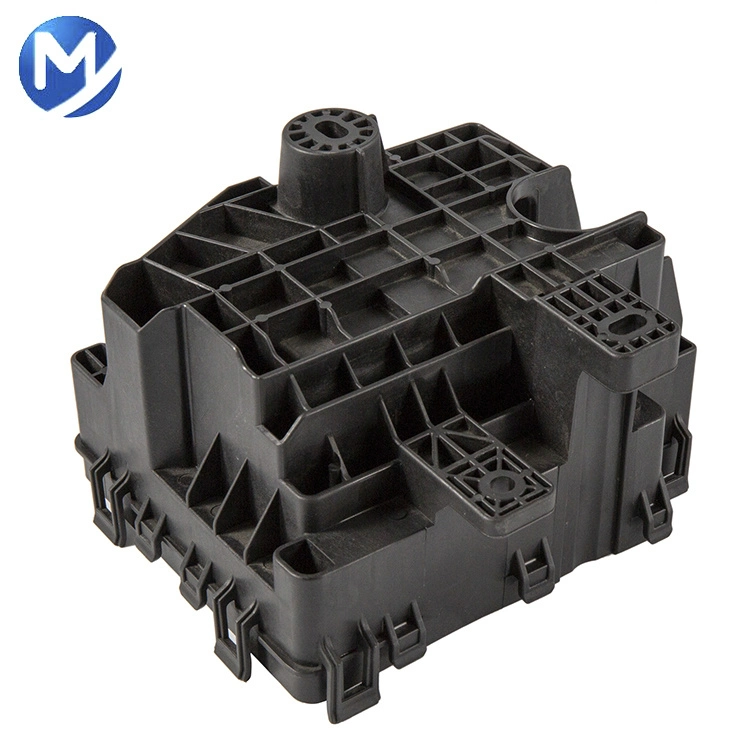

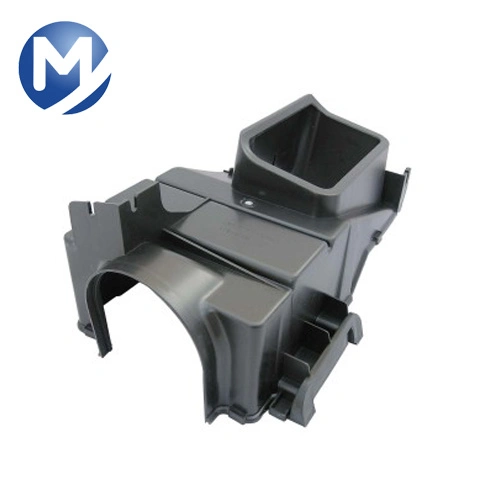

High Quality OEM Customized Plastic Injection Molding Parts for Electronic Product/Auto Parts

Basic Info.

| Model NO. | A0145 |

| Runner | Hot Runner |

| Certification | TS16949, ISO, FDA |

| Standard | HASCO |

| Customized | Customized |

| Cavity | as Per Client′s Requirement |

| Shape | Base on Drawings |

| Production Material | as Per Client′s Requirement |

| Mold Steel | Nak80, SKD61 |

| Cycle Time | 40s |

| Gate Type | Valve Gate/Open Gate/Sub Gate/Edge Gate |

| Transport Package | Carton |

| Specification | Customized |

| Trademark | MYMOULD |

| Origin | Shanghai, China |

| HS Code | 8480719090 |

| Production Capacity | 2500 Sets |

Product Description

Plastic Injection Molding Parts For Home Product/Electronic product/Industrial Product/Auto Parts

1-Start from part design analysis2-Mold design drawing and DFM report available so you can see how is the mold going to be before mold making3-If product is complex, moldflow report will be present as well4-In house mold making shop ensure you mold quality under well control. 5-Normally it takes 20-40 days to make mold, precise time depends on part design

Mould material | Plastic mould material: P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc... |

Fast mould design | Can be within 1-3 working days after getting customer's drawings |

Lead time | Plastic moulds: 3- 6 weeks after getting the mould design confirmation |

Mould testing | All of the moulds can be well tested before the shipments. Videos for testing the moulds are available. |

Minimum order: | Small orders can be accepted |

Production capacity | 100 sets/month |

Port | Shanghai |

Runner | Hot/cold |

Payment terms | L/C T/T Western Union Money Gram |

Mould making service | OEM/ODM service available |

After sales service | Available by our staff with more than 10 years of working experience in this field |

Good packages | In strong wooden pallets to avoid any damages during the long transportation |

Manufacturing and exporting experience for over 10 years. ISO 9001 approved &TS16949 approved.

Products are supplied to over 50 countries.

One-stop service for aluminum profiles, plastic parts, rubber parts, and moulds. Save time and save money for you.

In-house mold design and building capabilities.

No reclaimed material used to ensure high quality.

Keep secret to your idea and your design.

24 hours (two shifts) / 6 days for production.

Professional design team, mold maker engineer. OEM/ODM service.

Professional QC and R&D teams to assure high quality.

Professional sales team. Good English capabilities and communication skills.

No MOQ.

Prompt delivery. For prototype: 3-7 days. Production orders can be arranged specially to meet customer's urgent demands.

Geographical advantages: Within 30 minutes to airport or sea port.