China Metal Casting Foundry Product Customized Aluminum Sand Die Casting

Basic Info.

| Model NO. | JBDWJ0019 |

| Coating | Diatomite powder |

| Machining Tolerance | +/-0.02mm |

| Standard | GB |

| Certification | CE, RoHS, ISO 9001:2000, ISO 9001:2008 |

| Terms of Payment | T/T, M/T, D/T |

| Order Lead Time | Urgent Orders 10-15 Days |

| Tax&Freight | Without Freight&Tax Included |

| Shipping Port | Shenzhen |

| Sample Lead Time | Urgent Order:3-5 Days |

| Mold Lead Time | Urgent Sample:3-5 Days |

| MOQ | 100PCS |

| Transport Package | Box Packing |

| Specification | 30*40*50cm |

| Trademark | Qiaoruixin |

| Origin | China |

| HS Code | 7201500010 |

| Production Capacity | 100000PCS |

Product Description

Product Specifications | |

Craft | Lost Wax Casting , Precision Casting , Investment casting , Dewaxing Casting , silica Sol Casting , Precision Die Casting , Sand Casting. |

Material | Stainless Steel(General SUS304,SUS316,1.4301),etc.,Stainless Iron(General 201,420,430),etc.,High/Middle/Low Garbon Steel(A3,Q235,45),etc.,Alloy Steel(General 20cr,20crme,20crnimo,40crmo,40crnimo,42cr,42crme,42crnimo)etc.,Brass(H59,H62,H75,H80),etc.,Red Copper,Bronze,White Copper and other materials,The above menu is for reference only, if you have special needs,please contact customer service staff. |

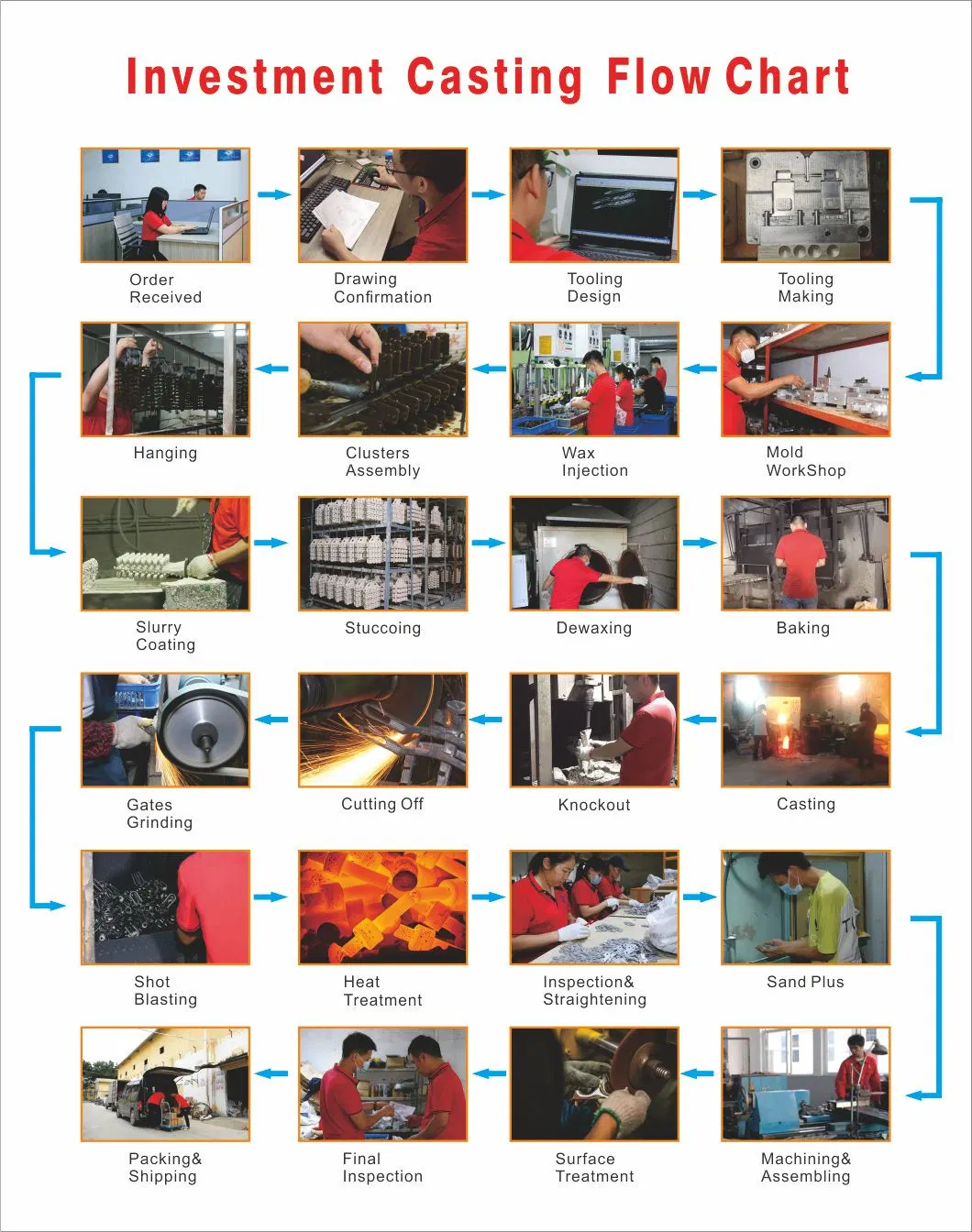

Process | Wax Injecting War repairing ,Tree Planting , Mucilage , dewaxing , investment , Shell Vibration , Polishing , etc... 48 Processes In TotaL. |

Post-processing | Ordinary Polishing , Mirror Polishing , Electrolytic Polishing , Brushed Finishing , Grinding , Heat Treatment , Finishing , Drilling and tapping , Plating,etc. |

Ordering Methods | We Can manufacture And Process According To Customer's Samples Or Dravings Designs;Meanwhile We Provide Some Ready Stock for Direct Order. |

Mold Lead Tine | Rush Order : 3-5 Davs . General Lead Time:7-10Days ( Peculiar Product Exception) |

Sample Lead Time | Urgent Sample : 3-5 days , General Lead Time : 5-7 Days ( Peculiar Product Exception ) |

Order Lead Time | Urgent Orders:10-15 Days , General Lead Time:15-20 Days ( Peculiar Product Exception ) |

Terms of Payment | The Mold wili Be made After 100% Payment Of The mold Fee , 50% Deposit Should Be Paid In Advance , The Balance Should Be Paid Before Shipment. |

Shipping Port | Shenzhen |

Tax & Freight | Price Quoted Without Freight&Tax included,For other requirements Please contact customer service staff |

The company has a total investment of more than 8 million yuan, with strong technical force and highly educated, high-quality, high-skilled professionals. The R & D team is dominated by postgraduates from top university, and post-doctors are the core of the team. It produces dozens of patents and inventions every year, and has strong independent research and development capabilities.In recent years, Jinbianda introduced various international advanced equipment successively and has solid technological foundation and advantages. To ensure the high quality of the products, we innovate actively, improves the production process as well as expand the outputs every year. We reach an annual output of more than 1000 tons of high quality metal casting parts and accumulating rich experience in both technology, quality and promotion.With excellent quality, reasonable price and perfect service Jinbianda wins favor and praise from the local and overseas customers. We serve customers in the mili-tary industry, automotive, mining, railway transportation, wind power, petroleum, electrical machinery, home appliances, door and window locks, medical, beauty and other industries. Our products exported to Europe, South America, Southeast Asia, Middle East and other countries and regions.

FAQ

Question 1: Do you have ready stock or only do custom order?Answer: We mainly do custom order according to customers' designs or samples, and a few existing models can be directly ordered for production.Question 2: What kind of materials can you do?Answer: We can produce stainless steel, stainless iron, carbon steel, alloy steel, brass, cupronickel, copper and other materials needed by our customer.Question 3: Which drawings and file formats can you accept?Answer: We can accept a variety of drawing formats, but the main formats are as follow:2D, PDF and DWG, 3D, STL, IGES, STEP, Solidworks, etc...Question 4: What is the delivery time for new mold and its sample?Answer: Our delivery time depends on casting and finishing requirements, but usually The mold and sample time is 10-15 days, and the mess production is usually 25-30 days after receiving the deposit. For urgent orders, please discuss with us!Question 5: Is it possible to visit your factory and check your manufacturing process?Answer: We sincerely welcome our customer to visit our factory. I believe you will leave a deep impression, we will discuss and learn together to make up for our shortcomings.Question 6: Could you please inform us your working hours?Answer: Our sales team works from 8:00 am to 18:00 pm from Monday to Friday. Factory working hours are from Monday to Saturday from 8:00 am to 21:00 pm.