OEM Silica Sol Sand Cast Iron Lost Wax Steel Die Casting Aluminum Gravity Casting with CNC Machining for Heavy/Textile/Electronic/Agricultural Machinery Parts

Basic Info.

| Surface Treatment | Sand Blast |

| Standard | GB |

| Certification | ISO 9001:2008 |

| Quality | High Level |

| Trade Assurance | Protect Your Order Everything |

| Item | Custom Homemade Metal Stamping Parts |

| Surface Finished | Sandblasting, Painting, Polishing, Poweder Coating |

| R&D | 3 Engineers for Electric Gold Plated Stamping Part |

| Sales Team | Response Within 24 Hours |

| Applied Software | PRO/E,Auto CAD,Solid Work ,Caxa |

| Inspection | 100% Factory Inspection in House |

| OEM Experiences | 13years |

| Sample | for Free |

| Delivery | 15-20working Days |

| Certificate Available | ISO,SGS,Certification of Raw Materials,Normal Cust |

| Experience | Since 2006 |

| Transport Package | Wooden Box/Cartons/as Your Need |

| Specification | OEM ODM parts |

| Trademark | YX |

| Origin | Shandong, China |

| HS Code | 73259910 |

| Production Capacity | 150 Ton/Tons Per Month Custom Stainless Steel |

Product Description

Product Description

Casting (metalworking)

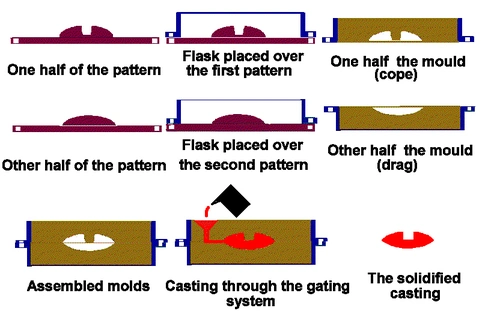

In metalworking, metal is heated until it becomes liquid and is then poured into a mold. The mold is a hollow cavity that includes the desired shape, but the mold also includes runners and risers that enable the metal to fill the mold. The mold and the metal are then cooled until the metal solidifies. The solidified part (the casting) is then recovered from the mold. Subsequent operations remove excess material caused by the casting process (such as the runners and risers).

Detailed Photos

| Typical | Feasible | |

| Shapes: | Thin-walled: ComplexSolid: CylindricalSolid: CubicSolid: Complex | Flat Thin-walled: Cylindrical Thin-walled: Cubic |

| Part size: | Weight: 1 oz - 450 ton | |

| Materials: | MetalsAlloy SteelCarbon SteelCast IronStainless SteelAluminumCopperMagnesiumNickel | Lead Tin Titanium Zinc |

| Surface finish - Ra: | 300 - 600 μin | 125 - 2000 μin |

| Tolerance: | ± 0.03 in. | ± 0.015 in. |

| Max wall thickness: | 0.125 - 5 in. | 0.09 - 40 in. |

| Advantages: | Can produce very large partsCan form complex shapesMany material optionsLow tooling and equipment costScrap can be recycledShort lead time possible | |

| Disadvantages: | Poor material strengthHigh porosity possiblePoor surface finish and toleranceSeondary machining often requiredLow production rateHigh labor cost | |

| Application Area: | Mining, Cement, Metallurgy, Ship-building, Bridge Construction, Power Plant, Oil Refine and General Machinery | |

Yinxiao Manufacturing provides you with one-stop service from Raw materials → Precision Investment casting, Lost wax casting, Sand casting, Die casting, Centrifugal casting, Sheet metal Stamping → Rapid tooling → CNC Machining → Surface Treatment → Quality Inspection → Timely delivery to customersWHAT WE DO:* Casting parts (Steel, stainless steel, carbon steel, Iron, gray iron, ductile iron, Aluminum, aluminum alloy, Copper, brass, copper alloy, etc.);* CNC Machining (Machining Center, Turning, Milling, Planing, Grinding, Drilling, etc);* Sheet metal (Stamping, Laser Cutting, Bending, Welding);* Plastic injection (polystyrene (PS), polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP), polymethyl methacrylate (PMMA), etc.);* Surface treatment (sandblasting, shot blasting, painting, spraying, electrophoresis, anodizing, polishing, electroplating, etc.);

Our Advantages

* One-Sotp service(from design to mass production)* OEM /ODM Customized services* Rapid prototyping & low-volume production* High quality & low prices* Highly skilled manufacturing process.* Strict quality Control System.

Our Service* Fast reactions and high efficacy Problems solving; * Have knowledge from part design, Quotation, Casting, CNC Machining to Finish; * Understand customer needs: product application, service environment, usage and so on; * Bring value to add we to customers and care about customer's business;

We are here, wish to be your friends.We promise that we can offer good quality&service on Casting CNC Machining, but for sure, more competitive price and better lead time.