OEM Liiquid Silicone Rubber Plastic Product Molds LSR Precision Parts Mould Making Custom Plastic Injection Molding for Medical Device and Healthcare

Basic Info.

| Model NO. | HM-IM PLASTIC |

| Mold Making | From Design to Manufacturing |

| Workshop Condition | 10K Cleanroom |

| Processing | Injection Molding |

| Material | Medical Plastic, Like ABS, PC, PP, LSR, TPU, etc. |

| Transport Package | Normally by Carton or Customized |

| Specification | Custom |

| Trademark | OEM |

| Origin | Guangfdong, China |

Packaging & Delivery

Package Size 6.00cm * 6.00cm * 6.00cm Package Gross Weight 0.080kgProduct Description

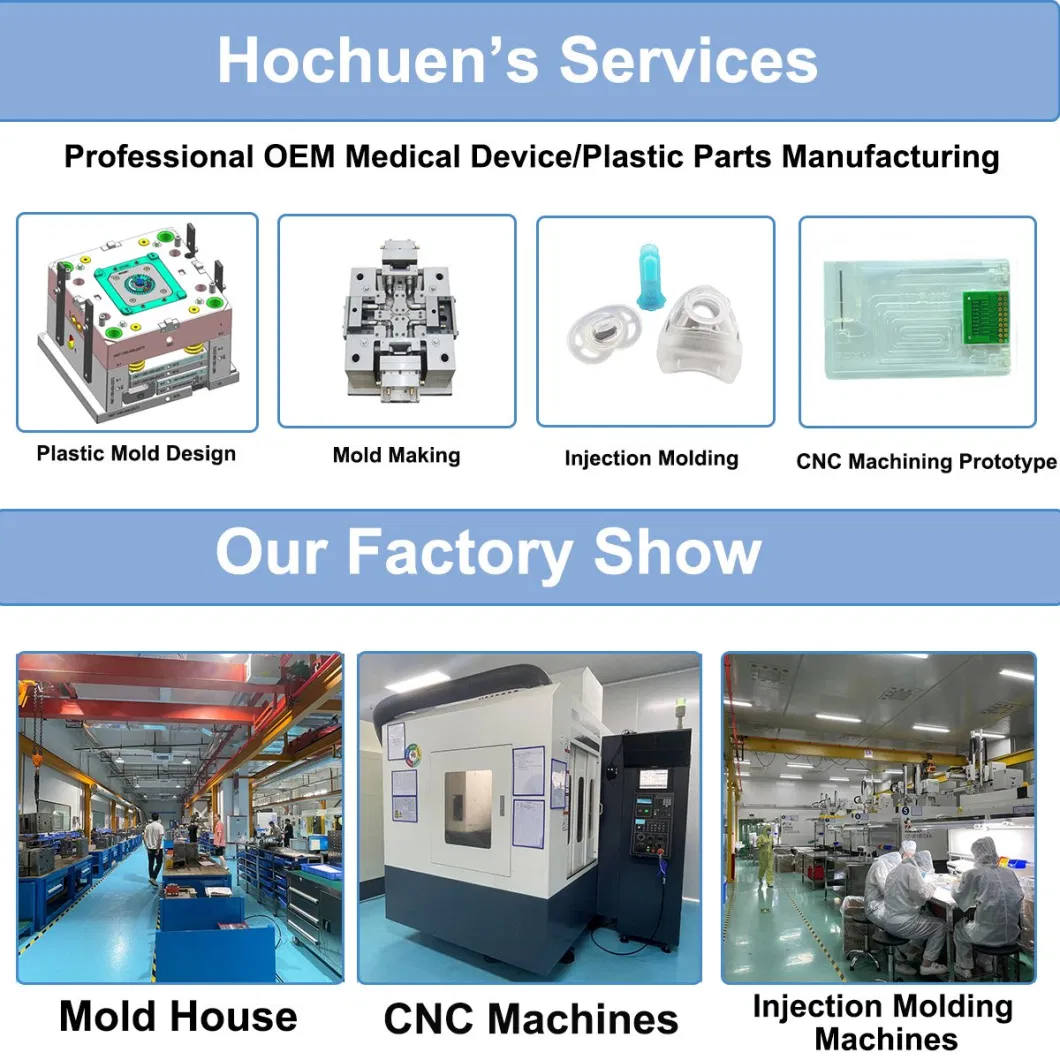

OEM Liiquid Silicone Rubber Plastic Product Molds LSR Precision Parts Mould Making Custom Plastic Injection Molding for Medical Device and Healthcare

Product Description| Company Name | Hochuen Medical Technology Co., Ltd. |

| Business Type | Manufacturer/OEM Factory |

| Manufacture Capabilities | Injection molding, microfluidic devices, adhesive, die cutting, lamination, LSR, bonding (including laser welding, ultrasonic welding, heat staking, etc.), dry reagent handling, reagent blister packing, wet lab process, PCR QC test, CNC precision machining, laser machining, rapid prototyping, label printing, softgood manufacturing, sterilization/packaging,etc. |

| Plastic Materials | ABS, PC, PP, PS, POM, PMMA, PE, PA, HIPS, TPU, PE, BOPP, EPDM, Liquid Silicone Rubber (LSR), etc. |

| Mould Precision | +/-0.01mm |

| Mould Life | 500,000 Times Shots or as requested |

| Mould Cavity | Single cavity or multi cavity for option |

| Runner System | Hot runner and cold runner for different products |

| CNC/Injection Molding Machines | We have Makino, Fanuc, Sodick, Sumitomo injection molding machines from 50 tons to 450 tons for prototyping and large volume production. |

| Advanced Testing Equipment | Prismo 3D equipment for inspection, 2D testers and other |

| Colors Available | Black, white, clear, red, blue, or according to customer's requirements. |

| File Format | Solidworks, DWG, PDF, AI, STP/STEP, etc. |

| Quality Management | ISO9001, ISO14001, ISO13485(ALL THE MEDICAL PRODUCTS MEET F.D.A STANDARDS), ISO45001 |

| Other services offered | Printing, die cutting, CNC machining, assemblying and packaging, etc. |

| Payment Method | T/T, PayPal or online transactions(by trade assurance) for option |

| Products Applications | Medical instrument parts and medical disposables, consumer electronics, sports, beauty and personal care products, baby's products, biosensors for DNA analysis or chemical research, Medical foams/tapes or thermal insulation pad for other biometrics,small parts for automobile, aviation and aerospace equipments, etc. |

| Prototyping | Drawings and quantities will be needed for a detailed quotation. Free Sample will be offered for approval after PO for molding is confirmed. |

Why should you buy from us not from other suppliers?

Experienced engineers; Quick actions; US subsidiary; Comprehesive processes, like printing, die cutting, CNC, injection and assembly.

Founded in 2000, Hochuen Group is one of the world's leading manufacturers of printing, precision die cutting products, and electronic accessories for consumer,industrial and medical devices. Hochuen is headquatered in Shenzhen, China, and has a branch company in California, USA, and is currently with over 100 engineers, 2,500 employees, and total 40,000 square meter facility. Hochuen is serving world-class customers(including a number of Fortune 500 companies) in various industries such as Medical, IT, Electronics, Medical (with FDA cleared products), Telecom, Automotive, etc. Hochuen's customers and suppliers are valued partners whom we treat with dignity, integrity and trust. Hochuen is an ISO9001, ISO14001, ISO13485 and FDA certified company. We are committed to providing quality products and superior customer services.

We are OEM manufacturer. For a detailed quotation, please provide us with below information:1. 2D & 3D vector drawings;2. Material and applications;3. Required quantities, and some other requirements.Hochuen is professional contract manufacturer for medical devices and other plastic components. Please feel free to contact us you need any support on your projects.

1.How do you cut the parts?We have laser cutting, die cutting, CNC machining and stamping.2.What Certificate do you have?We have certified with ISO 14001, ISO 45001, ISO 13485, and FDA registered.3.What kind of injection molding you do?Normally we have ordinary injection molding, double color injection molding, LSR, overmolding, insert molding, etc.4.What tons of injection molding machine do you have?From 50 tons to 450 tons, we mainly focus on consumable medical device, LSR (liquid silicone rubber) also available, and we do mold in house.5.How do you assemble the parts?Typically we have PSA bonding, laser welding, ultrosonic welding, diffusion bonding, etc.6.Are you available only prototyping or from prototyping to manufacturing?We are an OEM manufacturer, and provide one stop service from prototyping to mass production.All of our products are customized.